dft technology STOCK

Equipment and Services for Thermal Processing of Food

Subscribed

You have successfully submitted your enquiry. Someone from our company will respond ASAP

About Us

STOCK batch type retorts / autoclaves and plants are the focus of dft technology’s product range. Controls, documentation and SCADA systems represent perfectly balanced components, which are also available as retrofitting. Dft technology offers equipment for the loading and unloading of retort cages, as well as for other kinds of containers. A wide range of cages, spacer mats and trolleys complete the range.

Even, gentle and fast temperature distribution and cooling

- Product quality: one system for all requirements

- Variety of containers: flexible without compromises

- Food safety: oxygen-free processing

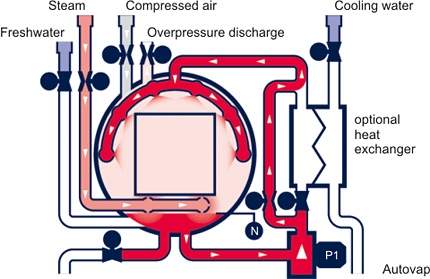

Energy contained in the storage vessel allows for extremely short temperature come-up-time. Water covers the containers, providing uniform temperature penetration into the product from all sides.

The steam counter pressure control in the storage vessel prevents pressure peaks and minimises stress to packaging material. At no process phase are containers in contact with air, meaning that oxidation of products is prevented. Even, gentle but nevertheless fast cooling prevents thermal shock and the post-sterilisation cooking effect. High temperatures, transferred swiftly into the product, ensure that the required lethality effect (F0-value) is obtained as fast as possible.

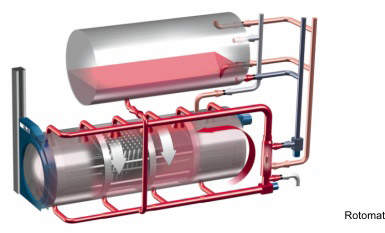

Forced convection, due to the rotary operation, accelerates the heat transfer to the coldest spot in the containers, even with products of higher viscosity. The short process times preserve natural quality, vitamins and nutritional values. Agitation of the product during heating prevents burning on the container walls. The end-over-end rotation in an intensely mixed process water environment with its optimal heat transfer ensures the HTST (high temperature – short time) processing of most products.

Minimal energy consumption steam-spray process

- Proven retort concept: a system with minimal energy consumption

- Designed for new packaging: flexibility in pasteurisation and sterilisation

- Product quality: process fidelity, short cycle times

If steam and water consumption have the highest priority, and the container material is suitable for direct contact with oxygen in the heating phase, the steam-spray process is the optimal solution. The directly injected steam blends with fine droplets of the water spray, resulting in a quick, homogenous heat transfer environment throughout the whole autoclave. As water jets spray into the cages, including from the sides, even and rapid cooling is safely achieved. The same results are also possible for comparatively flat containers.

This steam water spray retort / autoclave has low electricity, steam and water consumption. Safe counter-pressure control is maintained during all process phases. There is also optimal operation with part loads, assured process fidelity and it is suitable for different types and sizes of cages.

Fast cooling to low temperatures, with the use of a heat exchanger for indirect cooling, is ideal for pasteurised products in particular. In addition, the use of heat exchangers significantly simplifies the incorporation of the retorts into energy and water recovery systems.

Retort for thermal processing studies

- Qualified equipment for scientific and industrial studies

- Full / semi-immersion, steam-compressed air, saturated steam, water overspray

- Static and rotation process

- Process optimising and test production

- For packed food, pharmaceutical and industrial products

The dft technology retort series Pilot Rotor is suitable for scientific studies on the subject of thermal processing and practical industrial research. It can be used for production tests of all kinds and is particularly suitable for assessing new packaging materials and new types of food containers, as well as testing their behaviour during heat treatment. Moreover, it is possible to establish basic facts and decisive data for new recipes in order to obtain market-conforming, high-quality products.

According to the technical execution, the Pilot Rotor by dft technology STOCK is able to perform all known heat sterilisation methods. All containers or other packages can be processed in the static or rotary mode, axial or end-over-end. Rotation is clockwise or with alternating sense, continual or in intervals.

Inspection and maintenance of thermal processing equipment

Minor defects are often the cause for major issues. Reject batches or even production downtimes result in unnecessary costs that, in most cases, could have been avoided by regular and systematic preventive inspection and maintenance performed by dft technology’s well-trained service specialists.

Only dft technology offers service-experienced specialists and immediate availability of common spare parts. Customers signed to a service contract can obtain a discount on spare part deliveries.

Contact Details

Website

Email Address

Address

Neumünster,

24537,

Germany