TOTE® Systems

Materials Handling and Conveying Equipment

Subscribed

You have successfully submitted your enquiry. Someone from our company will respond ASAP

About Us

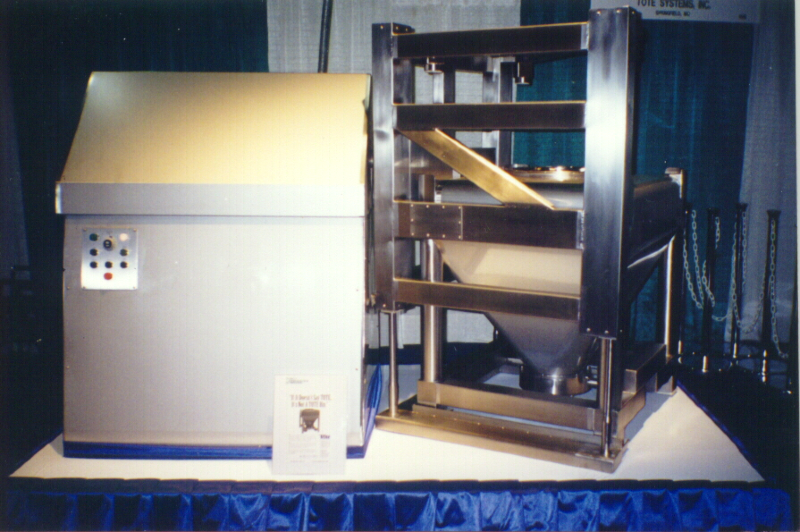

TOTE® Systems is a global manufacturer of dry powder and liquid-based material handling systems for the food and beverage processing industry.

TOTE® Systems is a global manufacturer of dry powder and liquid-based material handling systems for the food and beverage processing industry.

Since the introduction of the first TOTE bin in 1946, the company has now designed and manufactured a range of bins, as well as discharge and filling equipment, blenders and wash stations for TOTE bins and other apparatus.

TOTE’s turnkey solutions deliver throughout the bulk material handling process, from transporting and dispensing to blending / processing and packaging. Our team can support a range of projects, whether it’s a fully automated and integrated system or a single material that needs to be transported and stored.

Lab to full-scale systems for food processing applications

TOTE supplies a range of equipment, from laboratory-sized to full-scale production. Lab-scale equipment varies from 1/2ft³ to 10ft³ capacity on the TOTES.

For smaller labs, TOTE offers a tabletop blender that blends up to capacities of 2ft³. Our XL Lab Blender can handle blends of up to 10ft³. For full-scale production, we offer single pedestal, double-pedestal, and column blenders.

Blenders for dry powder and liquid-based materials

Known for their ability to achieve high blend uniformity within short times, TOTE blenders are an integral module in the TOTE material handling process.

The same TOTE container used throughout the manufacturing process also serves as the blending unit. This eliminates cross-contamination, costly production changeover times, and blender cleaning and preparation. It also considerably reduces the risk of separation by eliminating material transfers from container to blender and back to container.

Standard features of TOTE blenders include a top clamp on double pedestal and bottom clamp on single pedestal, safety interlocks, slow-speed start and stop, a product levelling feature, variable blending speeds and a remote operator panel, among others.

High-speed intensifiers for effective blending

In addition to standard in-bin blending, TOTE has introduced a high-speed intensifier to its blenders. This breaks up materials that tend to clump or stick together and is proven to enhance the blend, as well as leading to reduced blend times.

Tied to a variable frequency drive, the operator can increase or decrease the speed of the intensifier according to batch requirements.

About TOTE SYSTEMS

Since designing and manufacturing its first plywood TOTE bin, TOTE Systems has delivered solutions to a large number of projects around the world.

With installations across the US as well as in almost every country worldwide, TOTE continues to be a frontrunner in the food processing and pharmaceutical material handling business.

In addition to dry powder and liquid-based contained material handling products and systems, TOTE Systems also offers a wide range of engineering services and precision-cutting services for a variety of material types with waterjet cutting machines.

Contact Details

Website

Email Address

Address

Fort Worth,

TX 76140,

United States of America