Custom Air Knives for Unique Applications

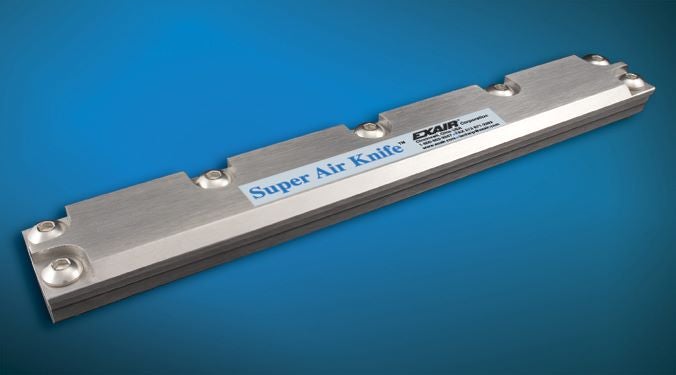

EXAIR’s Air Knives are an efficient and highly effective tool for blowoff, cooling, cleaning, and drying in a myriad of manufacturing processes. To accommodate the wide variety of unique problems manufacturers face, EXAIR has the ability to customise and tailor Air Knives to different specifications. These Air Knife customisations can range from size, to shape, to material, custom mounting holes, and dimensions. They are created to solve distinct manufacturing problems not already solved by the industry’s largest selection of Air Knives.

For customers with space limitations, smaller lengths or skinnier profiles can be created. In situations where the knife may need to be installed in a very defined spot, special mounting brackets, or additional/custom-sized air inlets can be provided to fit a current system. For applications where stock aluminium, stainless steel, or PVDF won’t work, other material options such as CPVC or glass filled PEEK thermoplastic have been used. Special marking requirements for tying knives to specific machines or critical processes can be accommodated. Unique shapes and profiles, such as double-sided or curved Air Knives, can also be the solution to certain specialised processes.

Air Knives are available in Super, Standard, and Full-Flow styles, and all versions are able to be customised to a customer’s specific needs. For help solving any specific blowoff problems, please contact Compressed Air Australia. All EXAIR Air Knives are CE compliant.

For more information, please follow the links on our profile.