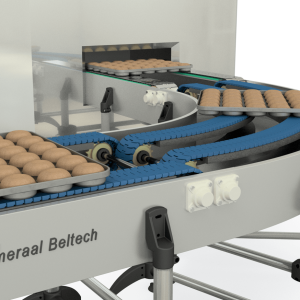

AmDough – Truly Endless Woven Belts for Rotary Moulded Biscuits

Ammeraal Beltech is a world leader in designing conveyor solutions. Its story began in 1950 when Thomas Ammeraal developed an endless woven bakery belt. It was a groundbreaking innovation, capable of high performance in extreme conditions. Since then, the company has been continuously surprising the market with further advancements.

Today, their solutions support bakeries across the world in achieving superior quality and safety of their products. The endless woven belts AmDough facilitate the operations of biscuit manufacturers, also the ones relying on rotary moulders.

What is a rotary moulder?

Biscuit production involves different equipment. Rotary moulders are machines that force the dough into the moulds, giving them shape and featuring with name, pattern, or docker holes.

First, the belt is squeezed between the moulding and pressure drums, and then it is released to create suction. Moisture and fat from the dough are absorbed into the belt, making the freshly shaped cookies stick to the belt. They are then extracted from the moulding drum and continue their travel to a knife edge. The fragile biscuit dough is released from the belt surface and continues to the oven.

Rotary moulders are valued for their consistency at high outputs. They secure the exact size, weight, and texture of the entire batch irrespective of conditions. The production is smooth and fast and offers consistent quality. However, using a rotary moulder entails a careful choice of the conveyor belt, and here is where Ammeraal Beltech can optimise your production line with AmDough – a truly endless woven belt.

How does AmDough support bakery processes?

AmDough was invented to provide better yield and longer belt life. The bottom side of the belt is impregnated with wear-resistant PU, and the edges are additionally reinforced. The structure is supported with cord, polyamide, and flax yarns. As a result, you receive the belt that maintains its shape and is resistant to wear and shrinkage, which translates into cost savings due to less frequent belt replacements.

Smooth product transfer is ensured by the absence of splices or seams. Scrapers can easily remove dough remnants without damaging the belt. Ease of cleanability combined with meeting food grade standards such as EC and FDA improve the Food Safety level of operations. The belt components do not transmit any colour, taste, or smell to the product conveyed.

AmDough secures uniform product quality. Belts have consistent extraction and release properties, preventing any deformations.

How to select AmDough

While choosing AmDough belts, pay attention to the factors influencing the extraction and release characteristics, which are:

- absorption capacity

- weave pattern

- belt thickness

Absorption capacity is determined by the content and combination of materials: cotton, fax, polyamide, and polyester. Ammeraal Beltech has an entire series with a nomenclature made of digits from 20 to 100 to show the extraction power of the belt from the moulding drum.

- The belt with the highest absorption and dough release capacity is the AmDough 100.

- The AmDough 50 is the most efficient type, able to mould and extract the majority of biscuits.

Concerning the weave pattern, AmDough belts are available with plain, twill, or broken twill weave. Different yarns and thicknesses can cover various needs and applications you need.

As far as belt thickness is concerned, a thinner belt can run over the smallest knife edge and follow its shape very closely to allow good release of the thinnest products.