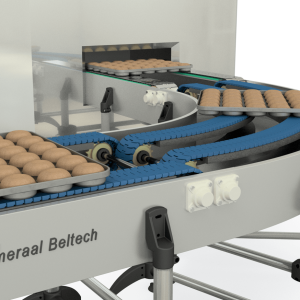

Ammeraal Beltech Introduces New Conveyor Belts for Bucket Elevators

Ammeraal Beltech, a global leader in providing conveying solutions, announces the launch of a new range of plied synthetic PVC-covered belts for bucket elevators – Arcon and Nonex.

In response to bucket elevator challenges

Ammeral Beltech regularly emphasizes its mission to provide top solutions for different industry branches. Its major concerns are innovation and optimization. Based on many years of experience and expertise, Ammeraal Beltech has developed two series of plied belts with synthetic covers for bucket elevators.

“We understand the challenges of the food bulk industry and want to deliver solutions that improve operational capabilities of factories worldwide,” notices Jaume Freixenet, Global ISM at Ammeraal Beltech. Here are just a few problems bucket elevators must deal with.

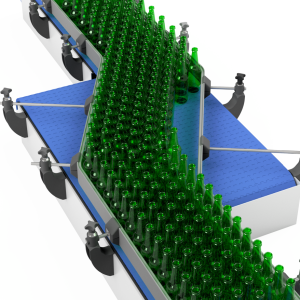

First and foremost, the transport of sugar, flour, and other grains and granular food should be carried out in hygienic conditions, following strict food safety standards. In addition, the transport of materials to a higher positioned hopper, silo or floor requires high strength. The belts should be carefully selected and installed with high precision. Otherwise, major consequences could include jams, bucket failures and broken elements. New Ammeraal Beltech conveyor belts meet these demands and set the ground for more.

Major benefits of Arcon and Nonex belts for bucket elevators

Arcon and Nonex belts establish a solid alternative for conventional multilayer cotton elevator belts and plied rubber-covered belts. These plied belts are finished with a PVC cover on both sides, bringing new quality into the game.

The major advantages of this new range of belts for bucket elevators include lower power consumption and longer belt life. This effect is achieved by the PVC cover, which is resistant to ambient conditions and the impact of the product conveyed. Buckets are less likely to tear the belt, and the material itself is proof against abrasion, oils, hits and harsh operating conditions such as high temperature, humidity and shock loads. Elongation is also lower because the solution is made of two or three fabrics.

Arcon and Nonex are also following the food and people safety concept. The belts have fabrics coated on both sides, which translates into a reduced risk of product contamination. Covers are easy to clean and guarantee greater food safety and longer belt life. The belts received EC, and FDA Food Grade certification with the last amendments 2021 about Simulant E migration tests and are approved for ATEX Category II for equipment operating in potentially explosive environments.

The solution also brings the following gains: reduced maintenance cost, high reliability, wear and oils resistance, as well as lightweight together with high loading capacity.

“Our belts are compliant with all standard requirements. They are not only Food Grade certified, but also have antistatic qualities and are flame retardant in line with ISO-340 self-extinguishing in less than 1,5 seconds,” notices Jaume Freixenet, Global Industry Segment manager Sugar & Bulk Foods.