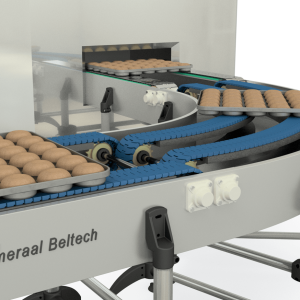

Ammeraal Beltech, the Food Safety Provider

At Ammeraal Beltech, we claim that the consumers’ health must be protected at all costs, as they put their faith in our Food Safety solutions. Our partners value the support we provide for the safety of the final customers, thus creating strong relationships on both ends. We are strongly rooted in this idea, and therefore we invest, engineer, and develop products to improve hygiene and safety at food processing plants.

We operate believing in ‘No compromise in Food Safety’. The constant expansion of our technologies and the expert application engineers responsible for new product development enable Ammeraal Beltech Food Safety solutions to set new standards surpassing the previously standardised ones.

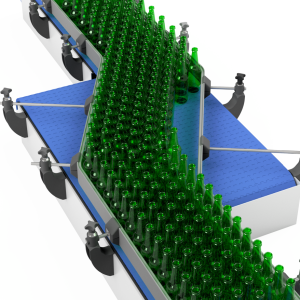

To better understand the Ammeraal Beltech product range, it must be mentioned that we always direct it at businesses searching for resource efficiency, the highest Food Safety standards, and sustainable belting solutions. We introduce products saving water and energy, and also, design them to run quietly and smoothly to provide a safe and failure-free performance.

Ammeraal Beltech food grade solutions

Food Safety belting expert is a label associated with Ammeraal Beltech. The reasons for that are seen throughout our revolutionary techniques of contamination prevention in segments such as Bakery & Confectionery, Meat & Poultry, Fruit & Vegetable, and more. We offer a comprehensive range of belting solutions for a wide variety of application conditions in the Food Industry.

To name a few:

Foreign bodies detection

Antimicrobial materials

Chemical resistance

Surfaces easy to sanitise

Non-stick properties

New standard products

Dectyl Synthetic Fabric belt protects the manufacturing line from torn belt particles. It shields your brand’s reputation and avoids costly product recalls. The matte finish has excellent non-stick properties and, together with the Ammeraal Beltech closed edges technique, the Amseal, it is a perfect product for segments handling sticky chocolate bars, dough and meats. Dectyl also comes in a version using a high grip for better positioning and inclined to convey.

Premium Plus range helps reduce system and maintenance costs while increasing output. Superior fabrics and Ammeraal Beltech non-shrink treatment used contribute to supporting Food Safety and preserving the quality of products. What is more, Premium Plus Non-fray technology together with a non-stick matt finish surface substantially limit cross-contamination and provide a longer service life.

Soliflex and Soliflex PRO are Metal Detectable homogeneous belts made of extruded polyurethane or polyester for many Food Segments. They have no layers, fabrics, or crevices, resulting in simpler and faster cleaning. Similarly, there is no risk of fraying edges and hence no risk of food contamination. Moreover, for even easier sanitising, scrapers are compatible with Soliflex PRO. This ultra-hygienic belt is also available in a mini version for transporting smaller foodstuffs and is installed on existing conveyors, allowing for on-the-spot washing.

Ultrascreen PRO is the newest Ammeraal Beltech Food Grade mesh belt proposition. It sets a new standard in terms of Food Safety in Fruit & Vegetable processing and Seafood handling. The belt, which is available in various mesh sizes, can be used in a wide variety of washing and dewatering applications. The Ultrascreen PRO belt employs the tried-and-true Soliflex PRO lug technology, which grants self-tracking and halts the need for re-tensioning. This Plug&Play concept avoids run-in time and ensures an extended lifetime. In fact, the Ultrascreen PRO prevents v-guide cracking and stainless-steel fastener tearing.

For a full list of Ammeraal Beltech Food Safety products, please visit the company website.