Revolutionise Your Bakery Production: Discover Ammeraal Beltech’s Cutting-Edge Conveyor Solutions for Ultimate Food Safety

In the busy world of bakery production, ensuring food safety is a top priority. Numerous challenges threaten the integrity of your products and the well-being of customers.

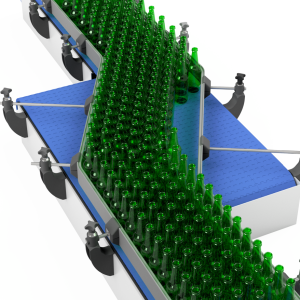

The adoption of innovative conveying systems enables you to enhance the efficiency of your processing line and protect the quality of your products and the trust of your consumers while guaranteeing high standards of food safety.

The challenges of bakery production

Within the world of bakery production, a myriad of complexities exists, each posing unique obstacles for manufacturers:

- Microbiological, chemical, and physical contamination risks loom large, presenting constant threats to product safety and consumer health.

- The management of allergens and prevention of cross-contamination stand as essential tasks, given the diverse dietary needs and preferences of consumers.

- Equipment malfunctions and improper handling can disrupt production processes, leading to delays, defects, and potential safety hazards.

The crucial role of belt selection in food safety strategies

Beyond Blue belts – commonly used to enhance food safety by aiding the detection of foreign particles and facilitating cleaning due to their distinctive colour – technological innovations, such as belts detectable by metal detectors and antimicrobial belts, offer advanced solutions to reduce contamination risk. It’s essential to choose belts designed for easy cleaning and resistance to product buildup, as well as investing in durable, crack-free solutions to ensure longevity and high hygiene standards.

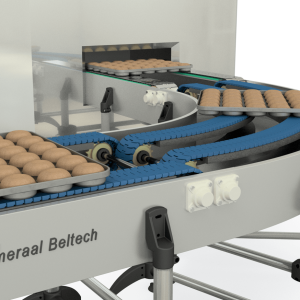

Ammeraal Beltech: Your recipe for safer food conveyor belts

Ammeraal Beltech stands out as a pioneer, offering a diverse range of conveyor solutions tailored specifically to the needs of bakery producers in compliance with rigorous food safety standards:

- Dectyl Metal Detectable belts show Ammeraal’s commitment to safety, preventing contamination from broken plastic belt parts and mitigating the risk of costly recalls.

- Flexible Nonex belts provide reliable performance in challenging environments, with high-grip, superior flexibility, and hygienic crack-free top covers.

- Duratemp belts offer exceptional durability and temperature resistance, ensuring longevity and reliability in high-demand bakery settings.

- Premium Plus range ensures top quality and optimal performance thanks to its excellent release properties, easy tracking, and reduced risk of shrinkage.

Through the comprehensive portfolio of solutions, including Soliflex XMD, Rapplon Homogenous Elastic Belts, Ultrasync, and uni Direct Drive Systems, Ammeraal Beltech continues to innovate conveyor technology, empowering bakery producers to navigate the complexities of food safety with confidence and success.

Ready to elevate your bakery production? Contact Ammeraal Beltech now to learn more about these game-changing products.