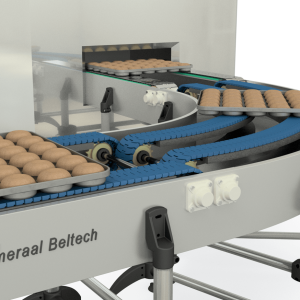

Food Safety solutions by Ammeraal Beltech

The Food Industry is a dynamic environment, influenced by societal trends and customer expectations. Increasingly, the topic of Food Safety regulations and standards is gaining traction in the field, with more and more companies improving their products in this manner. Ammeraal Beltech adheres to industry standards and innovates to protect consumers.

Looking back at 2023

The projects developed at Ammeraal Beltech during the past year have largely focused on Food Safety and how the conveyor belting industry can reduce contamination risks. The company has introduced over ten products focused on Food Safety. The solutions follow the company’s trend of continuous improvement, as they intend to build upon established designs to improve them. The goal is to adhere to the stringent standards and regulations imposed by the governing bodies, such as the EC and the FDA.

Detectable belts

The introduced products, all tested and Food grade-certified, answer a wide range of problems that industry specialists and producers might encounter. The problem of foreign plastic parts, such as belt particles that fall off during production and pollute food, can be improved with detection technology. Ammeraal Beltech has introduced a range of conveyor belts, designed to prevent belt particle pollution at early stages.

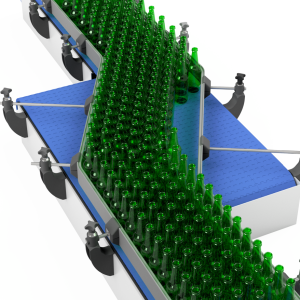

Ultrascreen mesh belts are mainly used to de-water and dry fresh-cut vegetables. Various mesh sizes of the screen material allow the ideal solution for each product size. This year, we have expanded the range with different variants, including the Ultrascreen XMD. The product is protected from contamination by its X-ray and metal-detectable side tapes and splices. If the detectable tape pollutes the food product, it will be picked up by the detector(s).

Those same solutions have been implemented in two other projects introduced this year – Soliflex XMD and elastic Rapplon Metal Detectable. Soliflex XMD is a belting range that is also designed to be detectable by X-ray and metal detectors supported by test cards to help the production line ensure better Food Safety. The new elastic self-tracking Rapplon belt is made specifically for food, beverage, and pharmaceutical industry applications. Its design helps filter out foreign bodies coming from broken belt parts from food, preventing contamination and ensuring Food Safety.

Why does Food Safety matter?

The topic of Food Safety and the measures production lines can take to ensure it is gaining traction. As seen throughout the products developed by Ammeraal Beltech in 2023, it is a focus point and innovation goal for the company taking part in the Food Industry processes. Ensuring customer safety is the top priority, and designing conveyor belts that can be easily detected is one of the first steps worth considering. The upcoming year will no doubt show the company’s commitment to the cause and the drive to evolve to fit in with strict regulations.

Contact Ammeraal Beltech or visit their website to learn more about their Food Safety solutions and how the company can aid your business.