WALDNER Process Systems

Process Systems for the Food Processing Industry

Subscribed

You have successfully submitted your enquiry. Someone from our company will respond ASAP

About Us

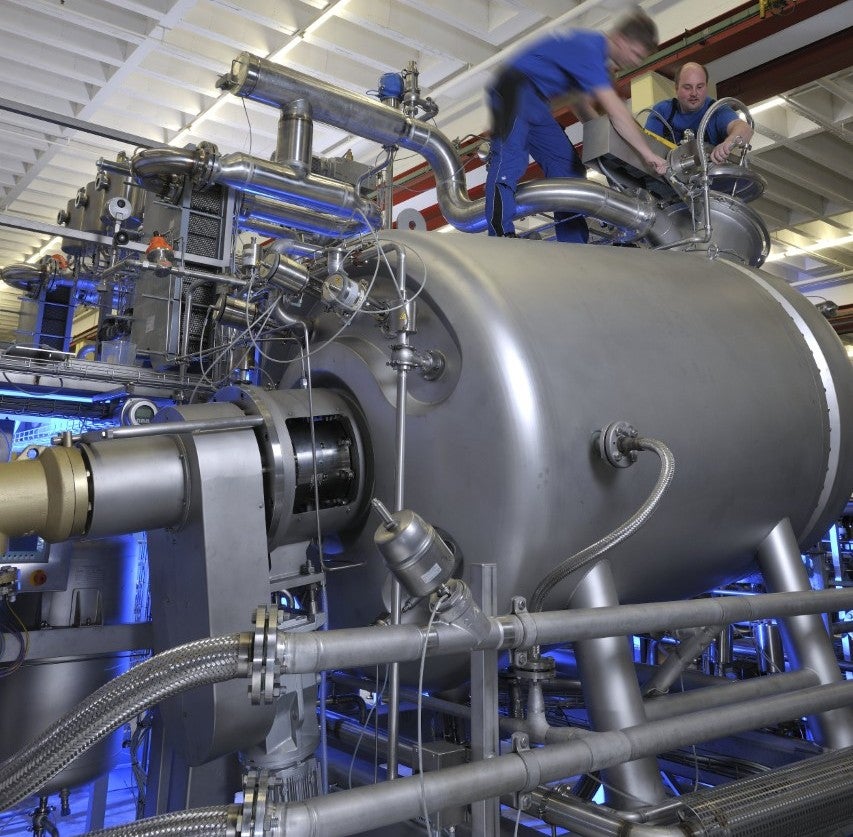

A business unit of the global WALDNER Holding group, Hermann WALDNER Process Systems provides process systems, vessels, isolators and cooking and packaging machines for the food processing, chemical and pharmaceutical industries.

The company’s name is also synonymous with laboratory furniture, which it designs and fits for scientific and technical educational institutions worldwide.

WALDNER Holding was established in 1908 by Hermann Waldner. With headquarters in Wangen, Germany, the strong and continuously growing group now has around 1,400 employees across four divisions: Process Systems, Dosomat (packaging and sealing machines), Water Technologie and Laboratory Furniture.

Across these divisions, WALDNER’s various systems dovetail together with ease. For example, WALDNER’s cooking and packaging systems coordinate seamlessly with each other in the same way that its process systems, isolators and laboratory furniture also fit together effortlessly.

From individual food processing solutions to complete systems

From single vessels to complete custom-made manufacturing lines, WALDNER’s Process Systems clients can find everything according to their individual needs.

Depending on the customer’s requirements, WALDNER can configure its products, including measuring, control and regulation technology, on a modular basis in all sizes and versions.

Custom-made process solutions for the food industry

Since being established more than 30 years ago, WALDNER Process Systems has already supplied over 25,000 individual solutions worldwide.

Always beginning with and prioritising your demands and requirements, cooperation with our customers begins with a professional consultation followed by process development, the design and execution of turnkey projects and the final qualification, as well as our maintenance service.

Material handling services developed by experts

Our experience extends across the food processing, pharmaceutical, chemical and healthcare sectors, where we offer a range of process systems.

These include isolators and full containment systems to protect our customer’s employees with the safe, contamination-free handling of highly active and toxic substances (APIs).

We also offer skids and packaging units for fast and reliable commissioning and qualification on site, ensuring fewer tests when setting up new units. Customers can purchase individual CIP / SIP units or complete preparation lines

WALDNER has a range of vessels, varying from single preparation, pressure and reaction vessels (including measuring and control systems), as well as round and cubic reusable stainless-steel containers.

The company has also developed drying technology, including mobile vacuum contact dryers for dust-free handling of powder, GMP-compliant vacuum tray dryers, and air-circulating and intermittent drying cabinets for the efficient drying of products.

Finally, we provide a range of different batch cooking lines for the food industry, including systems for the production of aseptic fruit preparations, fruit jams, sauces and soups. Our vessels are ideal for efficient cooking, stirring and boiling.

Food processing systems in compliance with ISO regulations

Our quality and environmental management system is certified according to ISO 9001 and ISO 14001. We are engineering in compliance with all current regulations, including PED, AD2000, DIN EN 13445, ASME, China License and TR certificates, ensuring our customers are perfectly equipped for all markets.

Please use the form on this page to send us your business enquiry.

Contact Details

Website

Email Address

Address

88239 Wangen,

Germany