SCHRADER

High-Quality Extraction Plants for Flavours, Fragrances and Active Ingredients

Subscribed

You have successfully submitted your enquiry. Someone from our company will respond ASAP

About Us

SCHRADER manufactures high-quality technologies for the extraction of flavours, active ingredients and fragrances for the food, cosmetic and pharmaceutical industries.

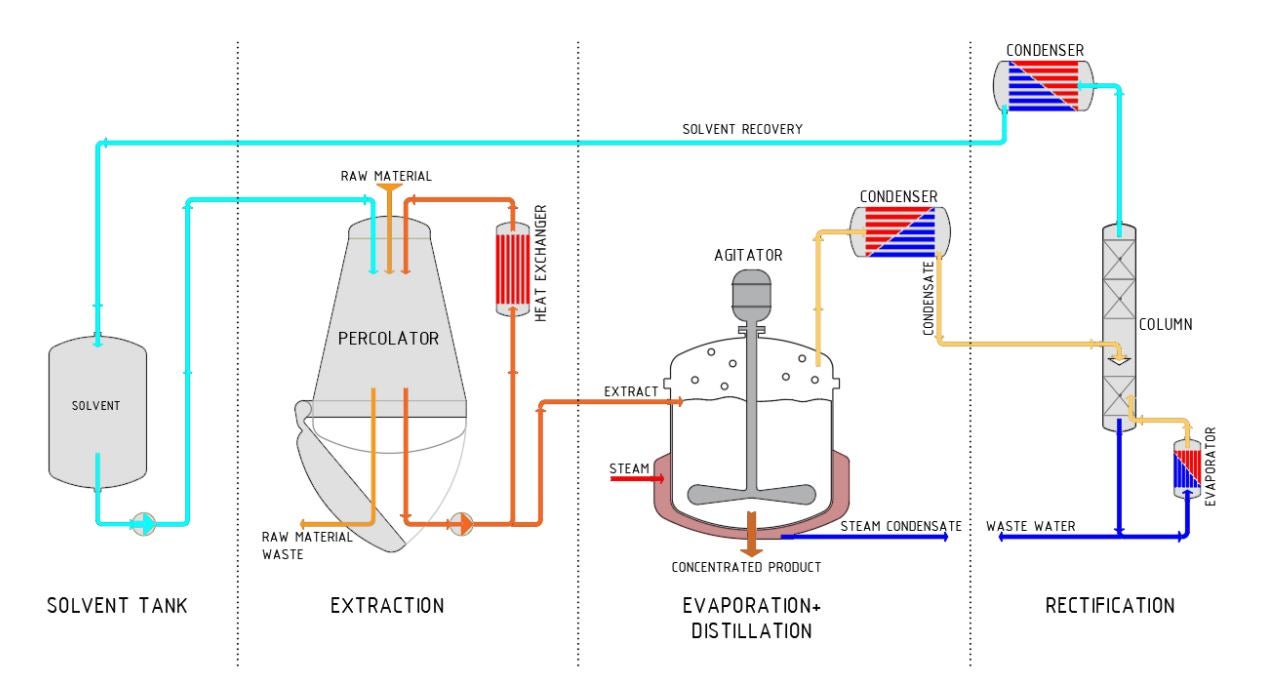

The company specialises in the design and construction of extraction plants, both including and not including downstream evaporation, distillation and rectification. SCHRADER also offers mixing technology and plants for preparation.

These solutions are customised to individual requirements and vary from single systems to complete turnkey plants.

High-quality extraction plants for food industry

Naturally occurring flavours, active ingredients and fragrances are found in a range of plant, animal and microbiological raw materials and can be extracted using enzymatic, microbiological or physical processes.

In addition to the interaction between the raw material and the solvent, important parameters in the extraction procedure include temperature, pressure, resting time and dosage. By adjusting all these, SCHRADER produces the optimal plant for each client.

On request, our plants can be designed in a way that enables halal and kosher-certified production processes.

Extraction process for flavours, ingredients and fragrances

The chosen extraction process depends on the type of product to be extracted, as well as the quantity of raw material (substance or mixture of substances). When required, SCHRADER integrates further processes such as evaporation, distillation and rectification into the plant.

Other related processes include mixing, dissolving, sterilising, cleaning, homogenisation and roasting, in addition to upstream processes such as grinding, chopping and swelling.

There are many natural raw materials that offer the possibility for flavour, ingredient and fragrance extraction. Examples include:

- Flowers: valerian, chamomile, St John’s wort

- Leaves: mint, sage, thyme, eucalyptus, tea, tobacco, cannabis

- Pods: vanilla, chilli, carob

- Roots: liquorice, ginger, turmeric, ginseng, rhubarb

- Animal products: cheese, meat, fish, feathers, hooves, glands

- Woody plants, barks: sandalwood, cola, birch, cinnamon

- Seeds, kernels: cocoa, coffee, dill

- Fungi: moulds, shiitake

- Fruits: citrus fruits, berries, olives

- Spices: clove, pepper

High-concentration vanilla extract from pods

Vanilla extract is a liquid extract made from vanilla pods in an ethanol-water mixture, sometimes with added sugar syrup. It is used widely in food, perfume and personal care products.

Pure vanilla extract, which can only be extracted from real vanilla pods, contains all the aromatic substances of vanilla in high concentration. It has an almost unlimited shelf life. In food processing, different vanilla pods are combined in a way that ensures a consistent quality level.

Custom-designed extraction plants

SCHRADER’s goal is to produce high-quality extraction plants that deliver reliable production to our customers. Working to specifications and in line with the necessary regulations, we design and manufacture highly specialised systems.

To do this, we use the customer’s objectives, process overview and our evaluated parameters to produce a plant concept that not only delivers in terms of extraction but also energy efficiency, sustainability and process safety.

Standards and regulations

SCHRADER places high levels of importance on developing and producing its solutions in compliance with the relevant standards and regulations, with complete documentation on Food and Drug Administration (FDA) and Good Manufacturing Practice (GMP) compliance provided.

In compliance with Annex 15 of the EU’S GMP guidelines, SCHRADER conducts the following qualification and validation activities for each plant:

- Design qualification

- Factory acceptance test (FAT)

- Installation qualification

- Operational qualification

- Performance qualification

In addition, SCHRADER’s operations comply with the European Commission’s food hygiene package, which was introduced in Germany in 2006 through the Food and Feed Code (LFGB). The rules enforce centralised food monitoring, control the combination of food and animal feeds, and place higher requirements on primary production (raw materials and additives), labelling and traceability.

Contact Details

Email Address

Address

59320 Ennigerloh,

Germany