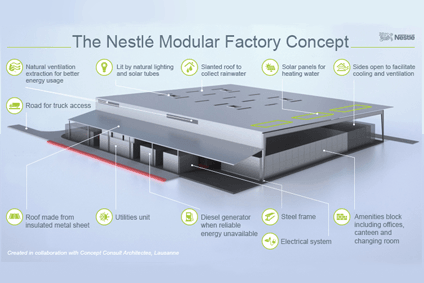

Nestle will begin to make use of modular factory building technology to meet its production needs, particularly in regions such as Africa and parts of Asia.

In an announcement released today (4 July), Nestle stressed modular factories can be built in “half the time” of traditional buildings, for 50-60% of the cost.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

On average, it currently takes Nestle 18-24 months and CHF30-50m to construct a factory. Using a modular approach, the company expects to erect factories in “less than 12 months” at a cost of CHF15-25m.

“The model is a real evolution from the traditional bricks and mortar factories of the past,” Alfredo Fenollosa, Nestle Technical Head for Asia, Oceania and Africa said.

“Big companies traditionally build solid stuff but the lighter structure of this modular factory concept represents a real mindset change for Nestle. We hope to be able to apply it soon in countries in Africa, and in some parts of Asia,” he added.

Modular construction – which involves assembling complete buildings using individual factory-built modules – is growing in popularity because it offers both flexibility and speed of construction. Modular factories can be expanded, moved or re-purposed without starting from scratch to meet future needs, Nestle said.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalData“The modular factory concept is designed to industrialise simple processes like repacking and mixing dry goods such as Maggi bouillon cubes, rather than creating more complex products,” the company said.