Integrated Extraction System

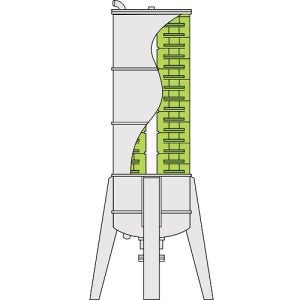

Flavourtech’s Integrated Extraction System (IES) is a continuous, automated processing line, which produces premium aromas, concentrates and extracts for instant and ready-to-drink (RTD) tea and coffee products.

Built as a modular system, the IES can be inserted into existing process lines as required to make gradual improvements, or installed in its entirety to form a continuous process line, allowing aroma recovery, extraction and concentration in one simple-to-operate system.

The IES process line can be operated with minimal staff and its easy-to-clean design allows different products to be processed with minimal downtime between runs.

IES modules available include:

- Slurry preparation module

- Flavour extraction module

- High-temperature extraction module (for instant coffee production)

- Solids separation module

- Clarification module

- Filtration module

- Wash module

- Concentration module

The IES is Flavourtech’s solution for those looking to deliver market leading instant and RTD tea and coffee products to discerning consumers worldwide.

Benefits

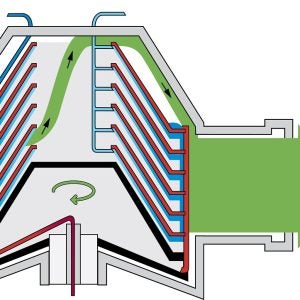

The IES system has been designed to minimise loss during processing by capturing the flavour of the raw material prior to it being subjected to high-temperatures. The fresh roasted aroma of ground coffee or light varietal tea flavour notes are captured at their peak, early in the process, and then added back to the concentrated extract at the end of processing.

The IES can process coffee, tea (including black, green, and oolong) and other botanicals without requiring any equipment changes. This results in minimal downtime between product runs, maximising factory throughput and efficiency.

The IES operating parameters can be readily adjusted to control the aroma profile and concentration of the product. The aroma profile may be altered by varying process parameters on the flavour extraction module. This enables products to be tailored to suit regional tastes and markets. Particularly suited to instant coffee production, the extraction module allows different temperatures to be used to enable selection of the best combination of yield to quality. The concentration module can achieve concentration ratios of up to 10:1 in a single pass, depending on requirements. Finally, the IES allows the aromas to be blended with the concentrated extract at different ratios, according to each customer’s preference.

As the IES is comprised of various stand-alone modules, the system can be installed gradually and added to as required. New modules may also be integrated with existing process equipment to enhance current throughputs.

The IES is available in two main sizes and with various combinations of modules that may be selected by the company in regards to taste, extraction and clarity requirements. Due to its compact and flexible nature it allows companies to easily install a line with minimal infrastructure requirements. Continuous and automated operation means that product is produced consistently, with a low-cost of production but with the ability to be flexible to produce a wide range of aroma and taste profiles.