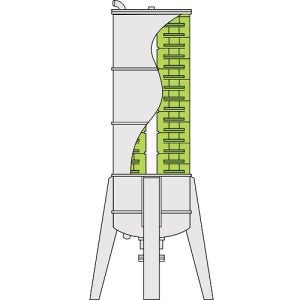

Rotating Disc Column (RDC)

The Flavourtech Rotating Disc Column (RDC) is a continuous contacting device for the food and beverage industry.

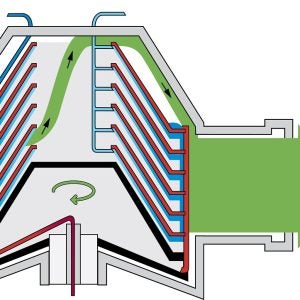

It is used when well-defined contact times are necessary for the soluble components to be efficiently transferred from within solid particles to a liquid medium.

The RDC allows temperature, pressure, and residence time to be controlled precisely to obtain near identical conditions for all parts of the mixture being processed, ensuring consistency in processing.

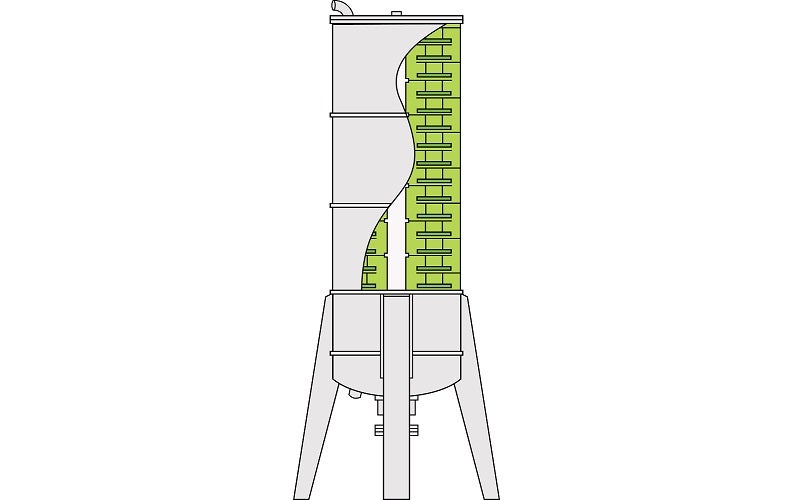

In contrast to batch tank processing, the RDC’s continuous and automated process means labour, energy, and overall production costs are reduced as time is not spent filling and emptying tanks.

Applications of the RDC include:

- High-temperature extraction of soluble solids from slurries in the instant coffee industry following the aroma recovery process.

- Continuous reaction processes in the food industry where precise temperature and times are required, for example enzymatic reactions.

- Continuous mixing of liquid/solid mixtures in the food and beverage industry for obtaining a consistently mixed product prior to feeding to the next step in the process line.

Benefits

The RDC’s unique design ensures the materials flowing through it are maintained in a state of continuous gentle agitation, preventing settling and the formation of static pockets.

The risk of over-extraction or under-extraction is greatly reduced as the RDC offers precise control of temperature and residence time during the extraction process.

It is ideal as a continuous feed mixing tank, feeding mixed product to the next stage of production. Typically, mixing is conducted batch-wise in stirred tanks, creating variations in the feed material quality and requiring a much larger footprint in the factory.

The highest quality coffee aroma is separated from a continuous flow of coffee slurry in Flavourtech’s Spinning Cone Column (SCC). Use of the RDC allows efficient, high-temperature extraction of the coffee slurry, downstream of this aroma recovery step. The aroma is then added back to the final product efficiently producing a soluble coffee that incorporates authentic roast-and-ground aroma.