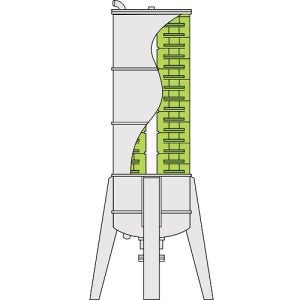

Spining Cone Column

New small-scale model for slurry processing now available

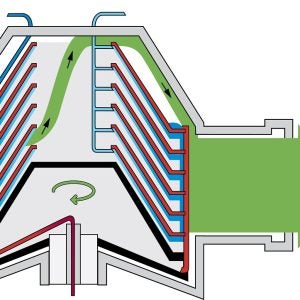

Flavourtech’s Spinning Cone Column (SCC) uses steam stripping to extract and recover volatile compounds in vacuum conditions.

This is a very gentle process compared to standard extraction techniques and enables better capture of aromas and flavours in a natural way.

Used across multiple industries, applications for the SCC include:

- Aroma recovery during instant coffee production

- Simultaneous flavour and soluble solids extraction from coffee and tea slurries for the production of Ready-To-Drink (RTD) beverages

- Essential oil extraction from botanicals, herbs, and spices

- Extraction of natural flavours from fresh fruit and vegetables

- Dealcoholisation and alcohol management in wine, beer, kombucha and other alcoholic beverages

- Deodorisation of cream and flavour management of dairy products

- Aroma recovery and preservation during production of fruit and vegetable juices and purees

- De-oiling of not from concentrate (NFC) citrus juices

The SCC helps deliver returns on investment through the recovery of flavours, aromas, and extracts by maintaining the natural characteristics of the raw material. The SCC operates as a continuous processing system delivering superb operational efficiency and maximising factory uptime.

Benefits

The unique design of the SCC enables it to process clear liquids and viscous products, such as fruit pulp and purees. Slurries containing high-levels of suspended solids such as tea and coffee can also be processed.

Using a simple chemical-free process where only pure steam is added to the product, the SCC meets the needs of consumers seeking nutritious and natural products.

The SCC is easy to use and allows companies to tailor the aroma profile they capture to suit consumer flavour preferences. Several operating parameters can be adjusted to control the type and relative proportion of volatile compounds extracted from the feed material.

Superior flavours are maintained using low thermal impact. Uniquely, the SCC uses gentle heating and a short residence time of only 25 seconds within the column. This avoids thermal degradation of the product being processed and ensures the best flavours possible are obtained from every product.