The demand for better, natural flavours in food and beverages will continue to grow as consumers gravitate towards healthier options and living. Manufacturers have had to adjust accordingly to meet this increased demand, plus contend with new legislation set by governments of countries or regions to meet higher quality standards, natural sourcing and labelling requirements. At times, new and improved processes have had to be implemented, for example, to capture the natural aroma of roasted coffee beans from the raw material itself before any high temperature affects are applied during instant coffee production.

A technology gaining momentum and much attention in the food and beverage sectors is Forward Osmosis (FO). Although the technology itself has been studied in academic circles for decades, the recent advances in material sciences have now made the technology feasible for commercial use.

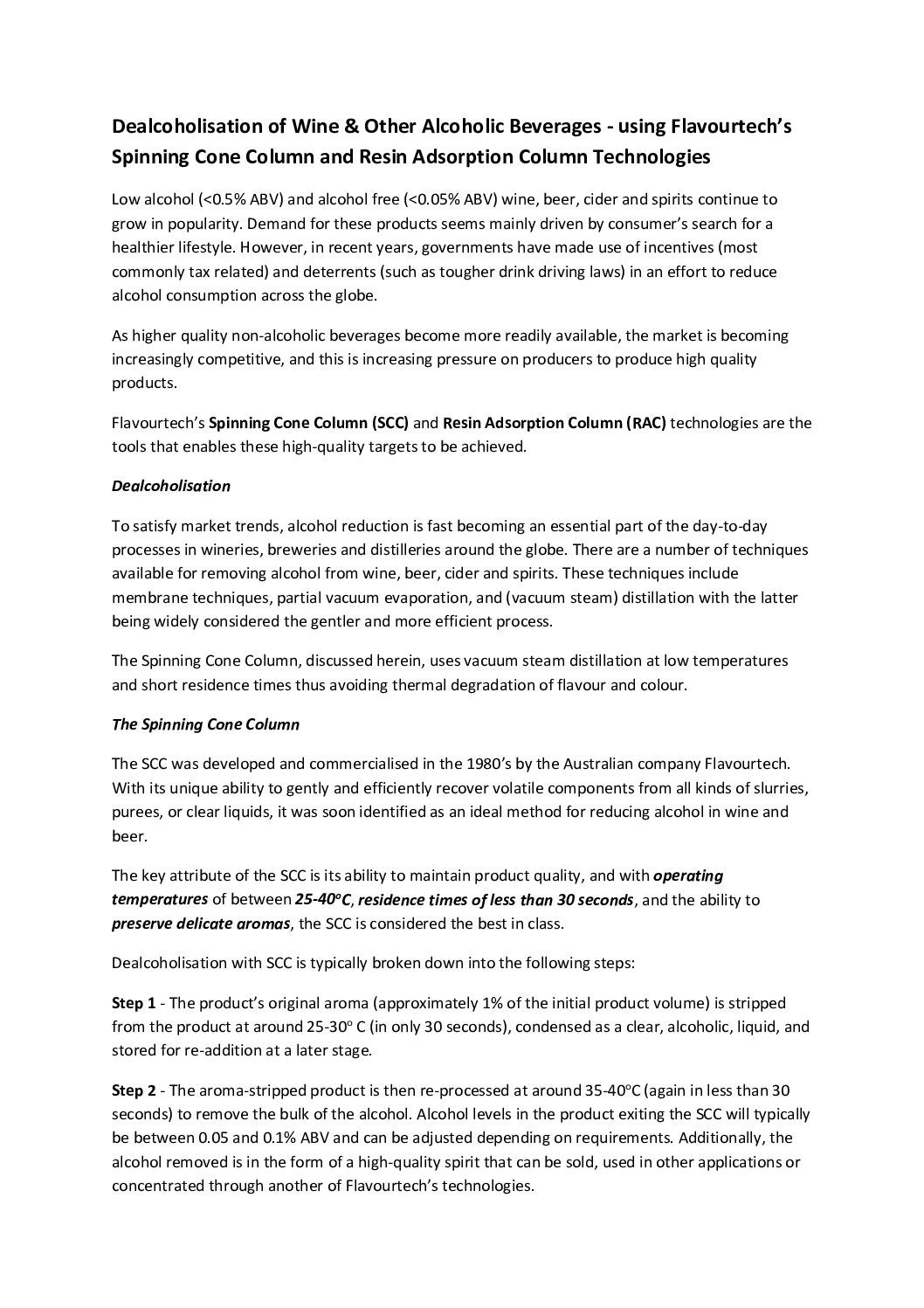

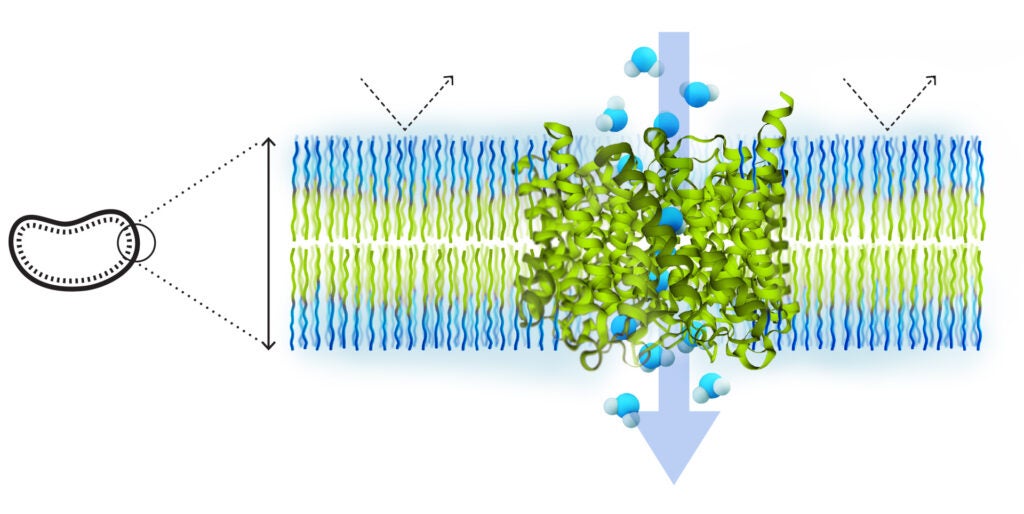

FO is a membrane technique relying on the osmotic pressure difference between two solutions on opposite sides of a membrane. In other words, water travelling from one side of the membrane with low solids to high, subsequently concentrating the former solution, due to concentration gradients, mimicking cell membranes in the human body.

The benefits of this process when compared to Reverse Osmosis (RO) include:

- Low hydraulic pressure

- Low operating temperature

- Low fouling of membranes

- Ability to process to higher concentrations

- Low cost of entry and operational expense

Flavourtech, an Australian manufacturer of food and beverage process systems, has been assisting manufacturers around the world in providing the means to produce the best quality with the highest levels of natural flavours and active ingredients for over 35 years. Examples of such products include those in the instant coffee, ready-to-drink (RTD) coffee and tea, low and no-alcohol wine and beer production and the natural flavours industry.

Flavourtech realised early on that the best way to obtain the best from products, whether it be flavour or active ingredients is to obtain it from processing the raw material where it is freshest and best (eg. flavour from roasted coffee beans, tea leaves, natural flavour recovery and protection from fruit and vegetables). Their process involves capturing these notes as early as possible, storing and protecting them. Their technologies often utilise shorter residence times and lower temperatures than competing technologies in order to reduce the thermal impact and so maintain the quality.

Aquaporin is a Danish water and process technology company specialized in membranes and systems based on its proprietary Aquaporin Inside® technology. By incorporating aquaporin proteins, nature’s own water channels, to improve efficiency of water separation.

Flavourtech has recently partnered with Aquaporin, a Danish manufacturer and a leader in Forward Osmosis technologies to further assist food and beverage manufacturers in providing the highest quality natural products. The Aquaporin Inside® technology is used for the purification of water (drinking and wastewater), but it is also used in the food and beverage industry where it is getting a lot of attention. The gentle nature of operation and efficiency of the FO membranes, has gained the interest of many coffee manufacturers and flavour houses who can see benefits by their business in obtaining significant gains in flavour retention and quality improvement.

For the coffee industry, the benefit of the FO membrane is in the ability to concentrate aqueous coffee aroma, as well as concentrate cold brew coffee extract. Natural coffee aroma is captured through Flavourtech’s Spinning Cone Column (SCC) where steam is used under vacuum to gently extract the volatile R&G notes from the roasted coffee beans. This SCC derived aroma can then be concentrated by removing the water using the FO system. A concentrated coffee aroma equates to less dilution of the concentrate prior to feeding to the spray dryer for the production of coffee powder. As less water needs to be removed by the dryer, less energy is being used in the process.

For the RTD market, there are significant savings in cost due to the reduction in volumes of water being transported where the bottling line is separate to the coffee extraction process.

Aquaporin’s Forward Osmosis membranes are also beneficial to the concentration of cold brew coffee. When it comes to sales of cold brew, manufacturers have to contend with the cost of logistics. Bottling plants may be at various locations – extraction in one city and then bottling in another, so being able to reduce the cost of logistics while maintaining the quality is of utmost importance. Normally concentration will involve an evaporator, where temperature is applied to the cold brew extract to remove water. FO on the other hand, does not require any heat. The FO process separates the water from the cold brew extract while maintaining the integrity of the product, a huge win for the manufacturer and consumer of Cold Brew.

Flavour houses can also take advantage of the benefits of this new natural concentration technology – a higher concentration of high-quality aqueous aroma equates to savings in packaging, space and transportation.

But it all comes down to the quality of the concentrate. The Aquaporin Inside® technology’s innate ability to better retain the flavours and aromas is key to success. Complex natural flavours from coffee, tea, fruits, vegetables, spices and herbs in an aqueous format are highly sought after. Having a concentrated version of this has the benefit of reducing dilution upon mixing and in reducing logistic costs due to transporting water around.

Food and beverage manufacturers are already taking steps towards this new technology. These are the leaders in the market who quickly take advantage of the latest technologies to stay ahead of competitors. They provide higher quality products that consumers appreciate. If you would like to be one of the leaders in this field then please contact Flavourtech and have a conversation of how we can assist in improving your flavours.

For further details, please visit Flavourtech.com