The relentless demand for no- or low-alcohol wines, beers and ciders has had a dramatic impact on the attitude to this sector. Manufacturers have scrambled to either enter the market or seek quality flavour improvements as competition heats up. The category has grown to a state where there are now dedicated shelves in grocery stores, entire bottle shops and non-alcoholic bars serving only no or low alcoholic beverages.

Whether one will call this an evolution or revolution in this sector, there is only one winner, the consumer, benefiting especially from the increase in the improvement of flavours of these dealcoholised beverages. Winemakers and brewmasters have been heeding consumers’ requests, aiming to achieve a final dealcoholised product that is similar in flavour and looks to the original alcoholic product.

Flavourtech, an Australian manufacturer of food and beverage process systems, has been assisting manufacturers around the world in providing the means to produce the best quality ingredients with the highest levels of natural flavours and active ingredients for over 35 years. Examples of such products are in the pharmaceutical, nutraceutical, food and beverage industries. Flavourtech realised early on that the best way to extract the best from products, whether it be flavour or active ingredients, is to obtain it from processing the raw material when it is freshest and highest quality (eg. flavour from roasted coffee beans, tea leaves, flavour recovery and protection for award winning wines and beers), and the concentration of solution through a gentle yet efficient evaporation process. Their processes involve shorter residence times to reduce the thermal impact when compared to other processes so as to maintain the quality of the end product, that is, the preservation of the bioactives.

But, why remove alcohol from an alcoholic beverage, why not start with a product with no or low alcohol in the first place?

The answer is fermentation. It is not just converting sugars to alcohol, but fermentation also allows intricate aroma compounds to develop, and these compounds in combination, are what makes consumers appreciate the taste of wine, beer and ciders. So, the winemakers and brewmasters are then tasked to find the best and the most trusted technique of removing the alcohol without loss of these sought-after compounds. Pioneers in this field Flavourtech’s Spinning Cone Column was specifically developed for the wine industry andis top of the list when it comes to producing the highest quality dealcoholised wine, beer or cider.

Dealcoholisation in the wine and beer making process

There are a few techniques available for removing alcohol from wine or beer. These techniques include membrane systems, partial vacuum evaporation and (vacuum steam) distillation, with the latter being widely considered the gentler and more efficient process. However, not all distillation technologies are created equal.

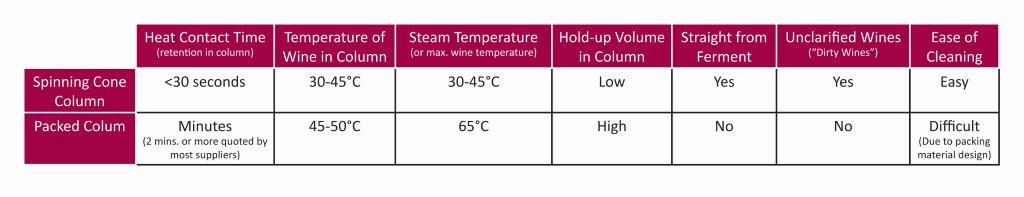

For example, Flavourtech’s SCC uses vacuum steam distillation with its key attribute being the ability to maintain the original flavour of the wine or beer. Operating temperatures of 30-45oC and residence times of less than 30 seconds result in the preservation of both the wine’s delicate aroma and colour.

Other distillation technologies, such as packed columns, use higher operating temperatures of approximately 65°C and residence times of minutes, rather than seconds. These higher temperatures and longer residence times can result in damage to the wine’s original aroma and a lower quality dealcoholised product (see further information in Table 1).

Table 1. SCC vs. packed column distillation systems

The table above compares the SCC to packed column distillation systems. Winemakers and beer brewers around the world can see the benefits of their product being run through the SCC as it does produce a high quality dealcoholised product whether it is for alcohol adjustment, low or no alcohol final product.

Flavourtech’s new Resin Adsorption Column (RAC)

If the requirement is for a no alcohol ‘wine product’ (<0.05%v/v) the options include only adding part of the recovered aroma back to the dealcoholized product or using Flavourtech’s new RAC technology. This new technology, in conjunction with the SCC, allows the total volume of the original wine’s aroma to be incorporated into the final product while still achieving the <0.05%v/v target.

The RAC process results in a premium zero alcohol wine or beer product (<0.05%abv) without the need to add any external flavours. The RAC system can also be used to lean tainted alcohol streams removing undesirable aromas and leaving a clean spirit that can be used for the production of spirits or hard seltzer drinks.

There have been many comments and questions about this process, which have given rise to the myth busting list below:

- The product (wine or beer) is superheated or is exposed to high temperatures in the SCC.

Myth! The SCC temperature is maintained at 30 – 45°C under vacuum conditions. The SCC utilises steam as the stripping medium to “strip” out the aroma and alcohol, but with vacuum conditions, the steam temperature is also reduced to these temperatures.

- The dealcoholised wine is damaged or affected by temperature.

Myth! The process through the SCC is the gentlest of the distillation techniques with the shortest heat-contact time (of less than 30 seconds) and lowest operating temperatures.

- The wine or beer contacts air in the system causing oxidation or degradation.

Myth! As mentioned above, the column is under vacuum and so there is no air in the system. For wine and especially beer we can or do use clean water (treated through reverse osmosis or deoxygenated) as the stripping steam.

- The dealcoholisation through the SCC does produce losses of alcohol and water (wine water).

Myth! The aqueous alcohol distillate from the product during the dealcoholisation step is captured. This can then be further rectified through the SCC for separation to 70 – 80% v/v alcohol and water. These two fractions can then be utilised in other parts of the manufacturing process.

So, if you are a winemaker or brewmaster and are looking at a dealcoholised wine or beer, what should you do to select the right process? Like any major decision, do some research, ask questions and talk with others in the industry who are in the same situation or have been so in the past. If you really want to see your own product processed then Flavourtech has pilot plants available for dealcoholisation and welcomes the opportunity to demonstrate them to you.

For more information on the Spinning Cone Column and Resin Adsorption Column please visit www.Flavourtech.com