Single Phase IBC Mixers

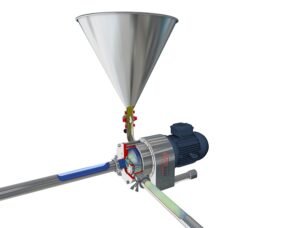

Mixquip Series, 200 unique range of IBC mixers, now includes 240V, single phase drives, making them ideal for small-to-medium-size businesses. The single-phase IBC Mixers are designed for use on industry-standard IBCs with a 150mm screw cap, with the high axial flow Superflo impeller, fitting through a 150mm opening to quickly re-mix the contents when settled out during transport or storage.

“Using the IBC as a mixing vessel ensures consistent product quality and savings on transfer and cleaning time.”

Applications

A wide range of products supplied in IBCs needs to be mixed before use to achieve optimum performance and consistent quality, including:

- Flavours

- Colours

- Chemical Industries

- Dyestuff & pigments

- Slurries

- Paint and Varnish

- Food & Beverage

- Cosmetics Industry

- Water treatment chemicals

- Flocculants

Technical

Mixquip Series 200 Superflo cast 316 stainless steel impellers are manufactured in a range of sizes & blade configurations to facilitate effective mixing for a wide range of products. Duel or multiple impellers can be used for medium viscosity materials. In addition, ‘kicker’ impellers can be positioned close to the bottom of the IBC for mixing at low levels.

Enquiries / Ordering

Mixquip Series 200 Single Phase IBC mixers are supplied complete ready for use with 3m of lead and a 240V single phase plus. The single-phase IBC mixer range can be supplied with a variable speed control providing an instant, cost-effective solution for products that need to be quickly re-mixed after transport or storage.

Please mention the mixing duty together with the product SG and viscosity or a description of the product to enable our application engineers to confirm or propose a suitable IBC mixer for your application.