Subscribed

You have successfully submitted your enquiry. Someone from our company will respond ASAP

When considering whether to install a top or side entry mixer on a large vegetable oil blending tank, process engineers should carefully select the equipment required to perform the duty, reliably and most cost-effective manner.

A top entry mixer requires a long shaft and large heavy impeller combined with a suitable heavy duty drive and gearbox to carry the forces generated when mixing.

Top Entry Agitators also require a mounting structure or reinforced tank top, to carry this additional mass. Baffles are also required if the Top Entry Mixer is mounted on centre. All these factors add together to make the top entry mixer a more expensive option to purchase and install.

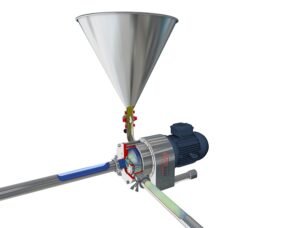

The Side Entry Mixer, is, as the name implies, mounted low in the side wall of the vessel. This means is has a shorter, lighter shaft and the axial flow impeller is smaller diametre, to create maximum flow in lower portion vessel. Being close to the bottom of the tank also means easy access for ‘installation and maintenance of the Side Entry Mixer. Side Entry designs also eliminate the need for in-tank baffles or anti-vortexing structures. Mixquip have had four decades of experience in both top and side entry mixer designs and will optimum selection of mixer for mixing large tanks.