Juice Pasteurisation

New findings from a Tetra Pak research group indicate that some juices are being over-pasteurised and wasting energy, money and time in the process.

Based in Australia, Teralba’s key brands include Mixquip®, Dimpleflo, Accutherm, and Rummager®.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

Teralba Industries is an established manufacturer of a wide range of fluid process mixers, food mixers, agitators, and heat exchangers for applications in the food processing industry.Based in Australia, Teralba’s key brands include Mixquip®, Dimpleflo, Accutherm, and Rummager®. Teralba’s team of engineering staff work closely with customers to determine their requirements, enabling the company to deliver the solution that exactly meets specific application demands.

Teralba Industries is an established manufacturer of a wide range of fluid process mixers, food mixers, agitators, and heat exchangers for applications in the food processing industry.

Based in Australia, Teralba’s key brands include Mixquip®, Dimpleflo, Accutherm, and Rummager®. Teralba’s team of engineering staff work closely with customers to determine their requirements, enabling the company to deliver the solution that exactly meets specific application demands.

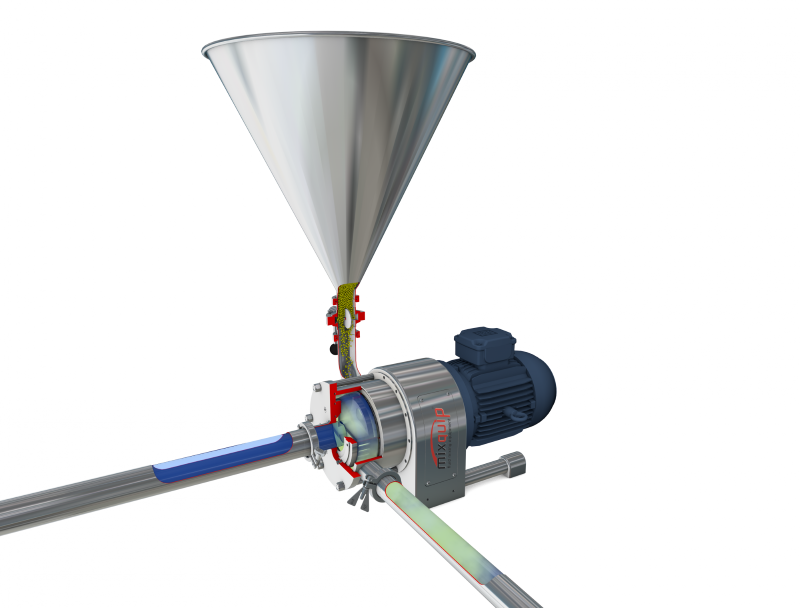

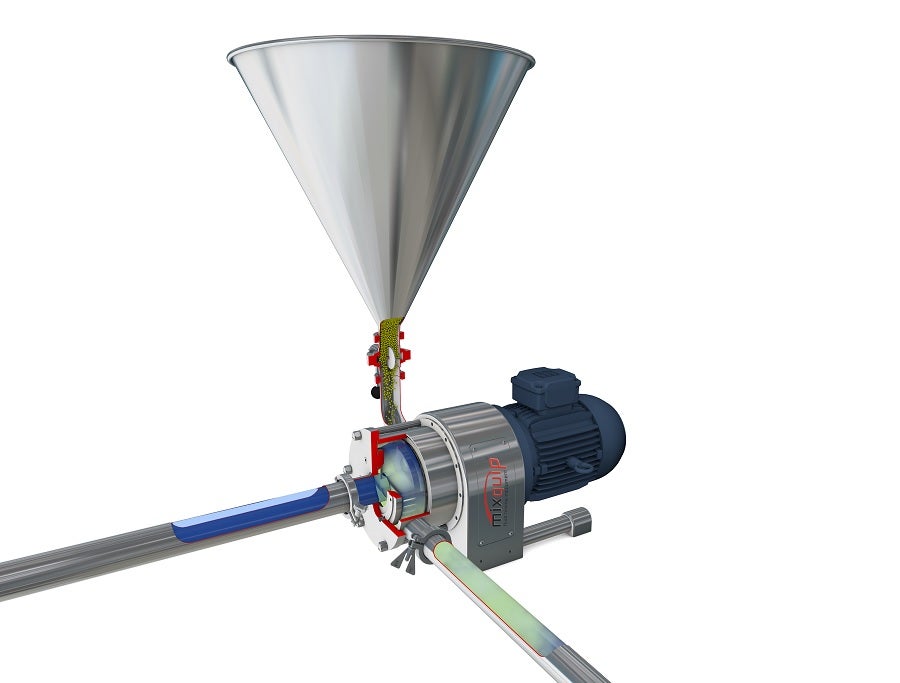

Mixquip High Shear, Series 620 Powder Liquid Disperser, disperses extremely difficult-to-whet powders into fluids quickly and consistently, without fish eyes or clumping. This premium quality, Australian-made, high shear disperser takes a ground-breaking approach to powder/liquid mixing.

Where most powder/liquid mixers use a vacuum to suck in powders, thus leading to aeration, the Series 620 Disperser actually shears the powder fines into the fluid stream. This allows it to disperse and hydrate large quantities of powders into high viscosity liquids and has been proven across many food, beverage, and pharmaceutical applications and products.

Suitable for mixing fluids of light-to-medium viscosity, the Mixquip clamp on mixers/agitators can quickly be fitted to open-top tanks, transforming a storage container into an efficient mixing vessel. Featuring a flexible design with a universal clamp assembly, the shaft entry angle can easily be adjusted in two planes. From blending ingredients, mixing, or maintaining solutions in suspension, the adaptable agitator can be used for multiple functions due to its variable speed-electric or pneumatic drives.

Mixquip’s anchor mixers are ideal for use on medium-to-high viscosity food products. They work by inducing product movement through the complete batch, homogenising viscous fluids, and improving heat transfer. Contra-rotating anchor mixers have a secondary agitator that can provide a beating, pumping, or shearing action. Combining an anchor agitator with a high-speed disperser, Teralba’s dual shaft mixer feeds the mixture into the high-speed disperser blade while ensuring the contents are constantly in motion.

The Mixquip Series 205 drum stirrer is an effective mixer of low-to-medium viscosity liquids in closed drums. Using fold-out impellor blades for powerful agitation in radial and axial flow patterns, the Drum Stirrer achieves homogenous uniform quality product mixtures. The drum mixer’s dual mixing action enables fluids with high specific gravity solids to be held in suspension.

The Mixquip Series 300 Top Entry mixers use advanced mixing technology to achieve the efficient blending of liquids and powders, suspension of solids, pH correction, and aeration of liquids. Constructed from a wide variety of special alloy metals, this versatile mixer can be attached to an integral mounting on the vessel, or suspended from a support structure.

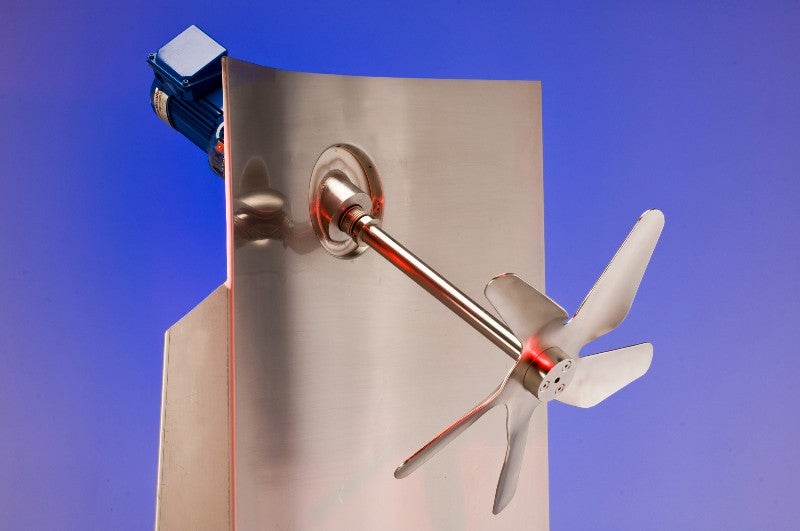

The Mixquip Series 110 Side Entry Agitator incorporates an innovative removable mechanical seal design and a high-performance Superflo agitator. The easy-to-remove seal significantly reduces servicing downtime, as it can be easily removed and replaced while holding liquid in the tank.

The state-of-the-art Superflo impellor provides low shear mixing with a powerful axial pumping stream, and is ideal for processing fluids such as wine, fruit juice, and vegetable oils, where gentle low shear mixing is required.

Dimpleflo tubular heat exchangers can be used for the heating and cooling of thick slurries, pastes, meat products, sauces, condiments, confectionery products, and more. The innovative Teralba ‘dimple’ increases the turbulence of product, reducing the total surface area required for a specific task. Each tube is self-draining, can be cleaned with “pigging” projectiles, and is made in compliance with the relevant standards and quality assurance procedures in Australia.

The Teralba Thermpro pasteuriser can incorporate the company’s Dimpleflo technology and is customised to suit client requirements. With the click of a button, the machine can clean itself, removing the possibility of operator error. In addition, Teralba has integrated remote access to enable visual inspections of the machine in real-time, allowing remote software updates.

Thermpro Static Block Melters incorporate all of the unique features of Teralba thermal systems, including a range of options for pumps, filters, valves, and temperature sensors. The system is ideal for handling controlled product melting rates. Thermpro melters produce liquid chocolate from many solid forms, all without altering the chocolate’s properties.

Teralba Industries’ clean-in-place (CIP) heating units use the company’s unique Dimpleflo technology to heat water, sanitisers, or CIP solutions with steam. Standard models can handle line pressure steam up to 13 Bar, eliminating the need for a pressure-reducing station. Heat is transferred efficiently, delivering significant cost savings on steam equipment. The units’ ultra-hygienic and compact design makes them ideal for CIP processes across a range of industries.

Each Teralba Industries product has been tested against stringent quality control measures and is stocked, assembled, and distributed from our Sydney-based factory. For more than 40 years, Teralba Industries has been known for tailor-made fluid processing solutions and providing quality customer service to our clients, ensuring that everything we design and manufacture results from a dedication to quality and innovation.

To request more information, please fill out the enquiry form.

New findings from a Tetra Pak research group indicate that some juices are being over-pasteurised and wasting energy, money and time in the process.

The Mixquip Series 300 Top Entry mixers incorporate advanced designs in mixing technology.

Whether your facility processes dairy products, meat, wine, juice or a multitude of other products, it pays to invest in a mixing system that will provide long-term efficiency gains.

Heat is used to manage dangerous microbial organisms that can be found in raw products. These days, there are many options to use, but heat remains the simplest, safest, and has stood the test of time.

Mixquip Series 100 Side Entry Agitators incorporate the best innovations we have developed since the first Teralba side entry agitator was produced in 1977.

VFDs change the RPM of an electric motor by altering the frequency and voltage, accurately controlling motor speed, can be used to great advantage.

Traditional powder-into-liquid mixers often use a vacuum to pull powders into the liquid stream, whereas the Mixquip 620 drives powder into the liquid stream.

Dispersion of powders and granules into liquids, remains one of the most enduring processing challenges in the Food & Beverage industry today.

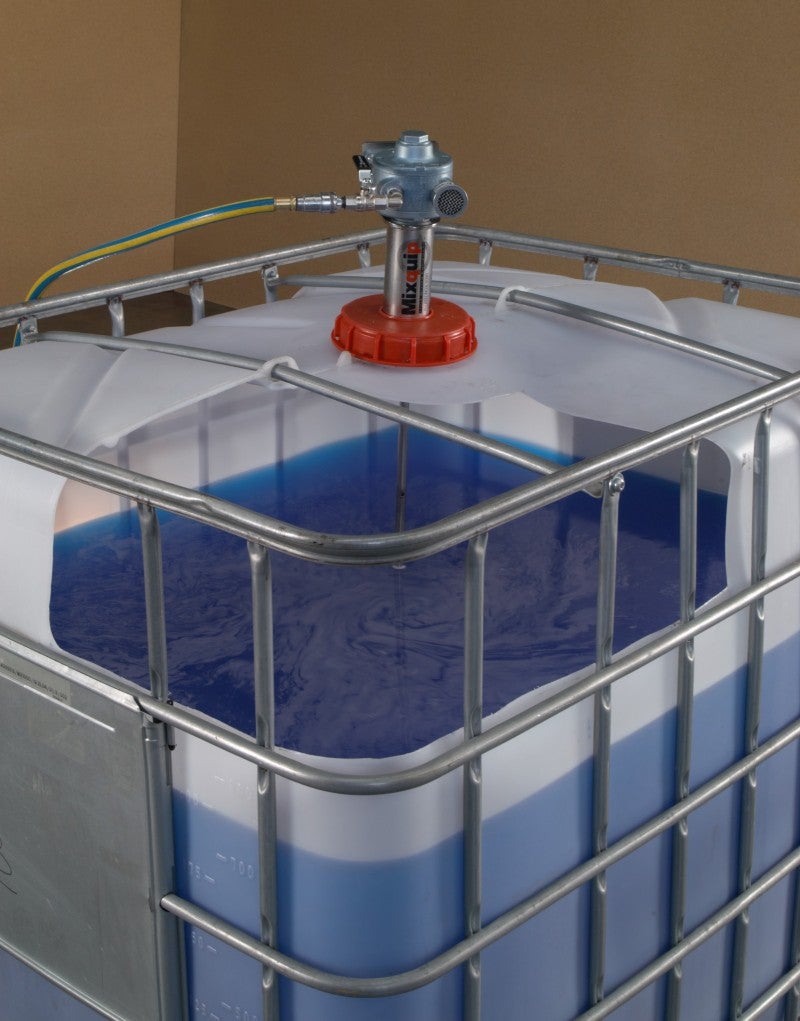

Australian designed and made Mixquip Series 200 pallet tank mixers can be used to mix, blend or maintain particles in suspension in any liquid shuttle or pallet tank.

Mixquip Series, 200 unique range of IBC mixers, now includes 240V, single phase drives, making them ideal for small-to-medium-size businesses.

Compact design and in-tank location make the Mixquip Portable Bung Mount IBC Mixer® simple to install and space-saving.