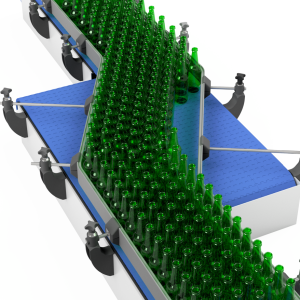

Transforming Beverage Glass Bottle Manufacturing with the uni ITB by Ammeraal Beltech

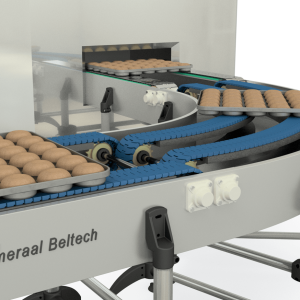

Ammeraal Beltech, a global leader in modular belt manufacturing, proudly presents the uni ITB – Industrial Thick Belt, a breakthrough innovation designed exclusively for the beverage glass industry.

This modular belt offers unparalleled efficiency and productivity enhancements, setting a new benchmark in glass bottle manufacturing.

Unveiling the Advantages of the uni ITB

- 0.5 inch belt thickness: the uni ITB was designed for high-demand beverage glass bottle production, ensuring seamless operations, reduced downtime, and high performance.

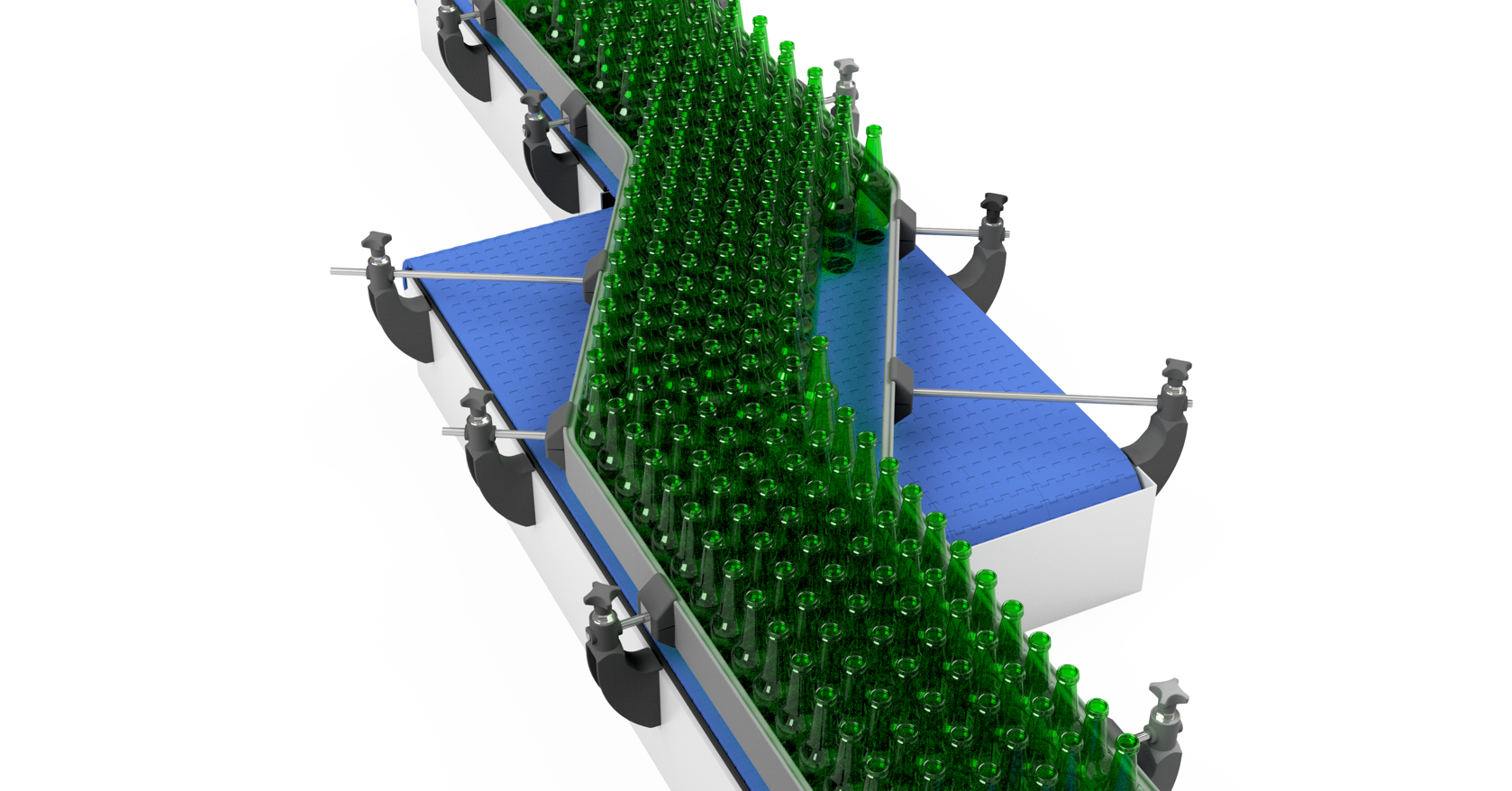

- 1.0 inch pitch: a smaller pitch minimises the polygonal effect and reduces tension fluctuations. Additionally, the link design enables smaller in-line transfer gaps for precise and consistent product conveying.

- Superior link flatness: the uni ITB ensures product stability during conveying, a critical feature for transporting fragile beverages, minimising waste, and guaranteeing that products arrive in perfect condition.

- Travel direction: uni ITB smoothly runs in both directions, offering versatility and adaptability to changing production needs.

- Solid close hinge: this feature enhances durability and wear resistance even in the most abrasive environments. This translates into lower maintenance requirements and a longer service life.

uni ITB UltraFit® Sprocket: A Perfect Match

uni ITB is compatible with both standard sprockets and uni UltraFit® Two-part sprockets, the timesaving and cost-cutting sprockets with built-in interchangeable adapters that ensure perfect sprocket alignment across the belt width and compatibility with most existing systems.

Elevating Glass Bottle Manufacturing to New Heights

With its exceptional performance and benefits, the uni ITB is destined to become the top choice for industry professionals looking to overcome their most challenging production issues and stay ahead in the competitive beverage market.

Do you want to experience all the benefits of uni ITB in your production line? Download our brochure.

Contact our experts to learn more.