Ensure That the Products you Send to Market are Safe

Food safety, sticky wet products, extreme operating conditions, and cleaning costs are all critical factors for the food industry. Embracing them as ‘opportunities for improvement’ can only add value to your business and help make you stand out from your competitors.

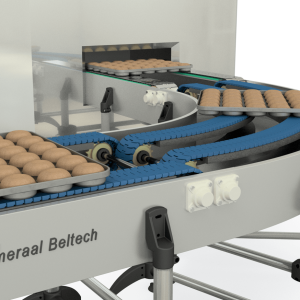

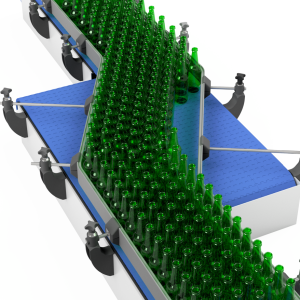

Contamination can lead to product recalls and loss of public confidence in food brands. That’s why Ammeraal Beltech, a global leader in food-safe conveying solutions, works closely with EUs and OEMs to provide you with some of the best solutions to help you maintain the highest food hygiene standards throughout your entire Fruit & Vegetable processing operations.

Food safety begins with our partnership

Ammeraal Beltech is constantly developing innovative belting solutions and accessories to make your food processing line ‘Safe&Clean’.

Safe means our belts are in full compliance with international standards such as EC 1935/2004, EU 10/2011, and FDA to help you achieve ISO 22000 (previously HACCP) requirements. Clean means our unique belt designs facilitate easy cleanability, as well as a drastic reduction in water usage, cleaning costs and detergent required, all while reducing the risk of cross-contamination.

Maximise your food safety with Ammeraal Beltech’s X-ray & metal-detectable conveyor belts range

Ammeraal’s Dectyl metal-detectable belts help you identify contamination from plastic belting parts in your products. Our XMD belt range, instead, is easily detectable both by X-ray and metal detectors, thanks to the food-grade detectable compound present in its body and accessories.

The XMD range features:

- Ultrascreen XMD mesh belts with detectable edges. Available in various mesh sizes, these belts can be used in many washing and dewatering applications.

- Soliflex XMD homogeneous belts, any fragments from which can be detected thanks to a field-proven sensitivity control testing method.

What is unique about the Dectyl and XMD belt ranges? They come with an Ammeraal Beltech set of test cards so that the minimum detectable size of belting parts from your detection equipment into your food processing line can be determined under actual working conditions.

Soliflex PRO and PRO mini belts offer the ultimate hygiene with a lower total cost of ownership. These unique ultra-hygienic blue belts and accessories are easy to clean in minimal time and have no risk of fraying edges, offering you higher standards of food safety. Soliflex range is available in different kinds of profiles and covers, making it perfect for various applications.

Self-tracking and no run-in time? All this is possible with Ultrascreen PRO

This positive-driven belt does not require crowned or lagged drive pulleys with v-guides. Ultrascreen PRO belt uses Soliflex PRO’s lug-proven technology, which ensures ultimate tracking and almost tensionless running, preventing the occurrence of tearing out of stainless-steel fasteners and the often maintenance of v-guide and edges.

What’s more, Ultrascreen PRO affords an open area of 30% to 64% making it easy to clean and disinfect for excellent sanitation results.

Do you want to replace your existing non-detectable belts on a one-to-one basis? Ammeraal Beltech’s Dectyl and XMD belt range is designed to make them quick and easy for you to install and replace.