The Field Guide to Food Powder Characterisation

This e-book contains detailed measurement data including the determination of density, particle size, powder flow, cohesion strength, compressibility, and permeability.

Anton Paar offers food testing, as well as quality control and research services for the food and drinks sectors.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

Anton Paar provides solutions in food testing and quality control processes. Our laboratory and process measuring instruments are used in the control of incoming goods, quality control and research throughout production in the food industry.

The product portfolio ranges from portable measuring instruments to high-precision automated laboratory or process measurement technology to individual industry-specific solutions.

When it comes to chocolate production, nothing is more important than the quality of the end product. At Anton Paar, we offer solutions across the whole process.

At Anton Paar, we know that dairy products are subject to strong quality control regulations throughout production and packaging which is why we offer a range of instruments to help you adhere to them.

Grain and starch can be difficult to process, store, mix, and pump. With our measuring solutions, overcome these challenges and fully control your production and your end product with our vast instrument portfolio.

With laboratory and process measurement systems from Anton Paar, you can determine more than 14 of the most important parameters for quality control and R&D in the beverage industry.

For example, the Alex 500 determines the alcohol and extract content in beer, wine, cider, spirits, liqueurs and sake. Customers can also measure the alcohol content in their beverages with Anton Paar’s Density Meters. They are the fastest, most intelligent benchtop density meters we’ve made to date, giving you compliance with a range of standards. Plus measure dissolved CO₂ and O₂ in the production environment with the CboxQC.

Anton Paar is based in Graz, Austria, and employs more than 4,400 people. We operate six other producing subsidiaries and 40 sales subsidiaries worldwide.

The company’s core competence, high-precision production, combined with its close contact with the scientific community, form the basis for the quality of its instruments.

Anton Paar is owned by the charitable Santner Foundation.

This e-book contains detailed measurement data including the determination of density, particle size, powder flow, cohesion strength, compressibility, and permeability.

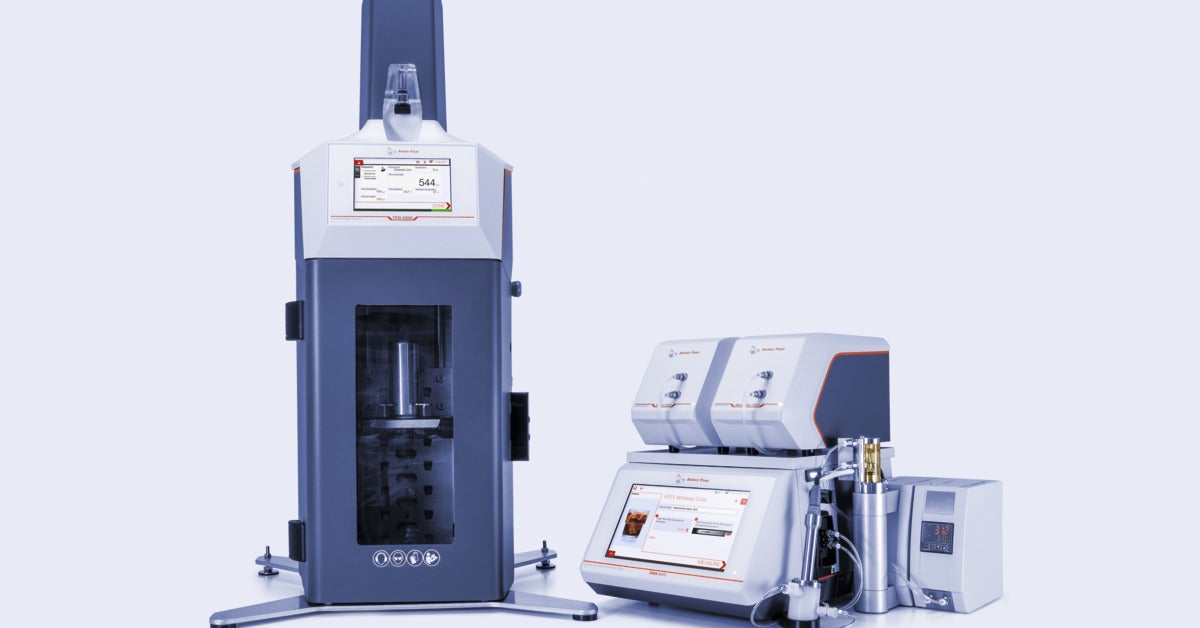

Anton Paar offers a new era of quality control rheometry with the launch of the MCR 53, MCR 73, and MCR 93.

Anton Paar has announced the launch of the Packaged RTD Measurement System, a dedicated solution for fast, precise analysis of ready-to-drink (RTD) beverages such as whiskey-cola, gin and tonic, and other mixed drinks.

Join Anton Paar for a hands-on food testing workshop scheduled for February 2026 that will offer food manufacturers practical insight into how integrated analytical techniques can support quality control, shelf-life assessment and product development.

Up to 35 % faster than comparable systems, the enhanced Xsample portfolio combines performance with intelligent functionality.

Reliable viscosity measurement helps you maintain mouthfeel, detect process deviations early, and optimise filling and pumping steps.

Reformulating products to meet clean-label expectations while preserving sensory quality and production efficiency requires precision, insight, and innovation.

This offer is designed to support laboratories and production facilities looking to upgrade their instrumentation for improved accuracy, reproducibility, and efficiency.

Maximum speed and usability for R&D and quality control.

The new MCR models are available immediately through Anton Paar’s global distribution channels.

In the highly competitive beer market, consistent quality and real-time process control are critical for brewers of all sizes.

Designed for seamless workflows, the Thermal Analyser features intuitive software navigation.

Anton Paar will host a live digital launch event on 1 October 2025.

The Alex 301 and 501 deliver results in under three minutes, with intuitive one-button operation.

The core of each density metre is the oscillating U-tube, which is now manufactured 100% in-house to ensure maximum control over quality and performance.

The highly anticipated Basics of Rheology Workshop will take place on July 30th and 31st, 2025, at Anton Paar Ltd. in Luton.

Anton Paar proudly introduces the L-Rix 2100 and L-Rix 3100, innovative inline refractometers designed for continuous Brix concentration monitoring in metalworking machines, industrial processes, and fruit and vegetable processing. With their unique combination of high precision, compact design, and affordability, these instruments set a new standard in reliable process control for industrial applications.

In the dynamic world of polymer processing, manufacturers face challenges such as material inconsistencies, efficiency losses, and sustainability demands. To maintain high product quality and meet evolving industry standards, advanced solutions are essential. Anton Paar offers a comprehensive portfolio covering process as well as analytical instrumentation.

Join us for a FREE expert session on measurement techniques in spirits distillation, processing, blending and bottling. Our experts will present our solutions for both laboratory and in-process testing, as well as automation and digitalisation options. Learn key techniques to optimise your processes and improve efficiency throughout your operations.

Anton Paar is delighted to invite you to join us for this comprehensive workshop on Polymer Processing and Characterisation. Tailored for industrial scientists and academic researchers alike, this workshop will equip you with essential knowledge and practical insights into polymer behaviour – from raw material to final product.

Anton Paar has launched its next-generation inline beverage analysers, Cobrix 5501, Cobrix 5601, Cobrix 7501, and Cobrix 7601. Features such as 'Measurement Check' and Cobrix’s advanced diet measurement bring a new level of quality control to the beverage industry.

Anton Paar’s Abbemat series of refractometers delivers highly accurate and efficient refractive index and Brix measurements, offering unparalleled support for quality control processes in the food industry. From raw material verification to process optimisation and final product analysis, these instruments ensure reliable results and operational efficiency for manufacturers and laboratories.

This workshop is aimed at those who are looking to find a solution to their viscosity measurement or customers who are new to viscosity. The workshop will involve theory and practical sessions.

Join us for a FREE expert session on advanced materials characterisation in food development with Anton Paar and Brabender solutions for quality control and formulation optimisation. Learn key techniques to enhance consistency, stability and performance in food products, including food modifiers and plant-based alternatives.

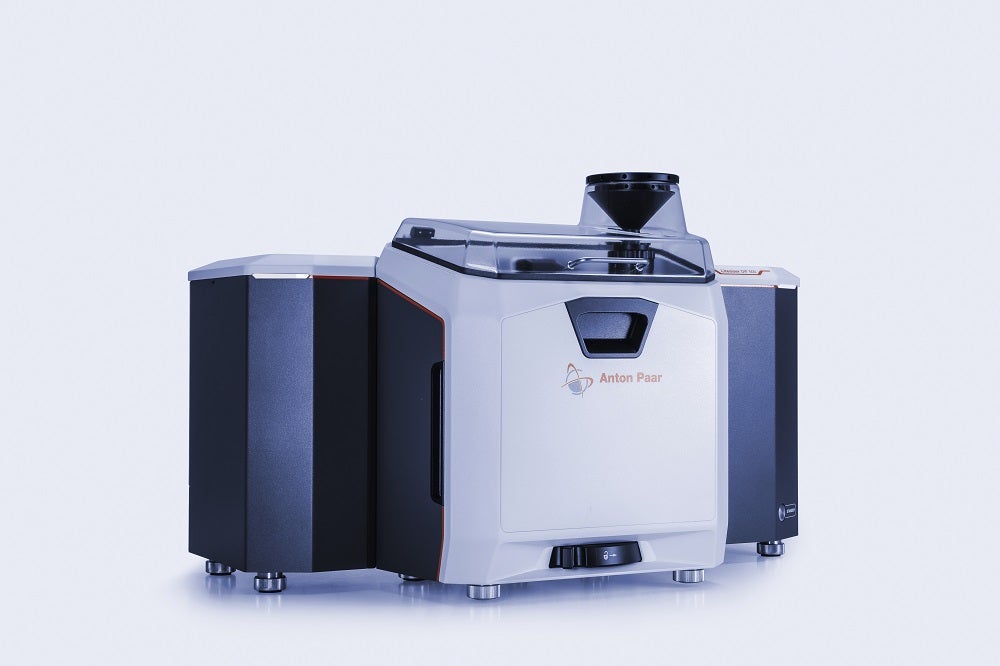

Anton Paar introduces SAXSpoint 500 and SAXSpoint 700, state-of-the-art laboratory beamlines offering unparalleled capabilities in SAXS/WAXS/GISAXS/USAXS/RheoSAXS analysis. Designed to meet the needs of researchers and industrial users, SAXSpoint instruments combine precision, flexibility, and efficiency, enabling comprehensive material studies under diverse experimental conditions.

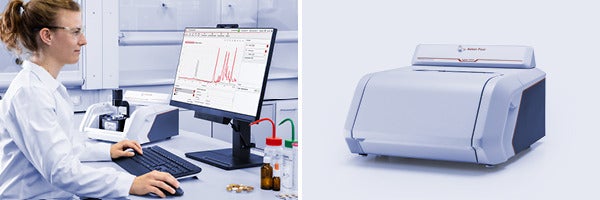

Lyza 3000 is the latest addition to Anton Paar’s industry-transforming Lyza series, offering a budget-friendly yet advanced FTIR spectrometer for comprehensive molecular analysis. This cutting-edge instrument simplifies material identification and verification.

Anton Paar announces the launch of Litesizer DIF 500, a laser diffraction particle size analyser designed to deliver accurate particle size measurements in high-tech laboratories and even challenging industrial environments. With the ability to measure samples ranging from 0.01µm to 3,500µm, Litesizer DIF 500 stands out for its precision and durability.

Anton Paar is proud to announce the new Litesizer DLS, a groundbreaking dynamic light scattering (DLS) instrument that sets new standards for particle analysis. Designed for precision, reliability and user convenience, the Litesizer DLS combines advanced features with intuitive operation, making it the ideal choice for laboratories seeking high-quality analytical results. Measure particles in the size range of 0.3nm to 12µm.

Introducing the latest version of AP Connect, a laboratory software that connects instruments from Anton Paar and other vendors, communicates measurement information, automates task execution and ensures compliance.

Different platform models can be equipped with up to four measuring heads, enhancing the measurement technologies with scratch testing, instrumented indentation testing, automatic conventional hardness, and tribology testing capabilities.

With its acquisition of Brabender, Anton Paar is excited to now expand its traditional portfolio of instruments for analysing food and feed.

Link Viscoelastic Behaviour and Molecular Structure with Live Raman Spectroscopy during Rheology Measurements

Anton Paar, a global leader in the development and manufacturing of high-precision analytical instruments, recently released its latest addition to its cutting-edge portfolio of analytical solutions.

Brabender Customers to Benefit from Renowned Anton Paar Service and Expertise.

After decades of experience in pressurised acid digestion and microwave technology, Anton Paar is proud to introduce the Multiwave 7101/7301/7501 series.

To ensure the hexane is then separated from the edible oil after evaporation and distillation, a quick and reliable method is required to determine the hexane content within specifications.

Our new Litesizer DIA 500 helps customers characterise the size and shape of particles via analysis of their direct images.

Customers can upgrade their existing benchtop density meter(s) of any brand including Anton Paar to the best-in-class density meter, DMA 5001.

Trade UP to two best-in-class products backed by the assurance of a three-year warranty and the Anton Paar service and support network.

The plant-based food industry is one of the most rapidly growing industrial segments in the world. A number of factors are contributing to this growth, the primary one being a significant increase in the number of consumers seeking vegan/vegetarian food options. Additionally, some consumers want to replace some meat-based protein with plant-based protein, for a healthier diet, and finally there is an increasing cultural desire to reduce the environmental impact and contribution to global warming caused by the beef and dairy industries.

Multiwave 5000 has been designed with the experience of over 40 years in sample preparation to meet the needs of today’s lab chemist.

If you need to analyse and monitor your food ingredients then take a look at these application reports.

Discover Anton Paar’s wide range of analytical instrumentation focused on food powder analysis.

Accurate control of the required NaOH concentration is important and can easily be accomplished with the superb Anton Paar density sensor L-Dens 7400 Version INC or sound velocity sensor L-Sonic 5100 Version MON.